PVC Floor

- Share

- Issue Time

- Oct 11,2017

1. English name

PVC (poly-vinyl chloride), Chinese name: plastic flooring, the current common name is PVC / LVT / LVP / WPC / SPC / Vinylfloor / vinyl plank. The main ingredients is the PVC material. PVC flooring originated in Europe and the United States, and is very popular in Europe and the United States, the Asia-Pacific region .China is currently more than 2.0MM commercial flooring, SPC, WPC floor is also slowly popular.

Plastic floor of the five common expression method

1.1 PVC: poly vinyl chloride,

1.2 LVT: luxury vinyl tile,

1.3 LVP: luxury vinyl plank

1.4 Vinyl floor

1.5 Vinyl plank

1.6 WPC: wood plastic composite (in fact, because the addition of wood powder processing and raw material recovery is difficult to deal with the current WPC floor substrate formula is no wood powder)

1.7 SPC: stone plastic composite, Europe and the United States called this floor for the RVP (rigid vinyl plank), rigid plastic floor.

2. The classification of plastic flooring

The current PVC sheet flooring can be made of two, one is from the bottom to the surface of the pattern material is the same homogeneous heart of the floor. If the surface was burned or broken, you can use a grinding machine wax repair The The other is the top layer pure PVC transparent layer and then add the following printing layer and the foam layer of the composite, visible, with the quality of the material than the composite type is much better.

From the morphological point of view, PVC can be divided into coil flooring and sheet flooring; this article focuses on the products: LVT, WPC flooring is semi-rigid sheet plastic flooring, and SPC (RVP) flooring belongs to the hard sheet flooring. At present, LVT flooring mainly has three types: vinyl locking, dry back, loose lay, another point of view, PVC flooring in accordance with the assembly method can be divided into: ordinary (Dry Back) lock (click) rubber (Loose lay). At the same time WPC wood flooring and SPC stone floor in the domestic and foreign markets are also in a positive promotion and rapid development stage.

2.1 Comparison of dry back and loose lay in plastic flooring

2.1.1 the same point: all belong to the PVC floor, the size of the same size, some of the same size;

Dry back are mainly 942 * 157,1227 * 157,1227 * 187,1227 * 235,914.4 * 101.6,470 * 470,608 * 308 (unit: mm) these eight specifications;

loose lay mainly 942 * 157,1227 * 157,1227 * 187,1227 * 235,470 * 470,608 * 308 (unit: mm).

Click the main specifications are 936 * 150, 1220 * 150, 1220 * 180, 1220 * 228,1500 * 228,600 * 300 (unit: mm).

WPC currently has two specifications 1217 * 146,1217 * 178,596 * 296 (unit: mm).

SPC are: 1210 * 150,1210 * 181,203 * 1219,178 * 1219,152 * 1219 (unit mm)

2.1.2 different points

A. installation method: dry back need to use hydrogel and other auxiliary, also known as glue down, loose lay can be paving (loose lay the bottom of the material above the layer of black, put on the plane to push.)

B. thickness: dry back Our factory is just starting from 2.0mm thick bottom, less than this specification does not do, loose lay is generally consistent with Click 4.0mm, 5.0mm

C. Wear layer: Under normal circumstances, we now do 2.0mm and 2.5mm thickness of the Dry back, wear 0.1mm-0.5mm, 3.0mm thickness Dry Back, wear to do 0.1mm-1.0mm, 2.0mm And 2.5mm principle can do more than 0.5mm wear, but from the cost is not cost-effective, in addition, the end of the material and the material in the formula have to change and test, and now the factory basically do not; loose lay At present, 4.0mm and 5mm wear-resistant layer of the basic only 0.3mm and 0.5mm wear, the same as above.

D. price: dry back cheap, loose lay more expensive

E. health time: dry back need 24 hours after tempering health, looselay and lock series, like 48 hours.

F: the flexibility of the two different, loose lay products are much better than dry back soft. Such a feature can also be used as a distinguishing feature. At the same time, the most obvious is the loose lay at the bottom of a layer of black, you can use the nail scraping to distinguish between hard and hard.

3. The composition of plastic floor

PVC floor components: PVC resin powder, stone powder, plasticizer, stabilizer, carbon black, the main component is polyvinyl chloride and stone powder.

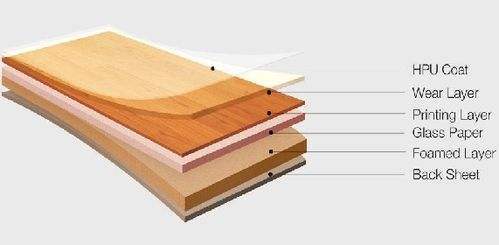

The plastic floor is composed of a backing layer, a core layer, a glass fiber, a decorative paper and a wear layer from the bottom to the surface.

1. HPU coat floor surface protective layer, blocking the room into the floor of the floor

2. Wear layer transparent polymer layer, to protect the floor color is not worn

3. Print layer simulation of various materials color, determine the effect of floor pavement

4. In the material layer polymer material layer to ensure that the floor size and stability

5. Glass layer mesh structure, balance the vertical and horizontal stress floor

6. Back sheet polymer materials, the floor by the cold heat control shrink

PVC certification

At present, PVC product certification is Floor score, DIBT, CE, ISO14001: 2004 and ISO9001: 2008, TÜV Rheinland.

PVC the most critical product targets

• Stability: Product shrinkage expansion rate 80 ℃ 6 hours. 0.25%, 0.15% (line)

• Heating warpage: 80 ° C 6 hours EN <2mm; Enterprise standard: 1.2mm (dryback); 1.0mm (click); 0.5mm (loose lay)

• Locking tension: room temperature (23 ℃) 5.0mm> 13-15kgs / 5cm.

• 4.2mm> 12kgs / 5cm.

• Short side If V buckle, 4.2mm> 15-18kgs / 5cm.

• Peeling strength: The strength of the color film and the material

This is also a small skill to judge the new return

• Scratch-resistant, wear-resistant

• Brightness: 10 +/- 2.

The floor to buy area calculation: If you need pavement area is 50 square, because the floor to the corner need to cut off part of the general floor of the loss rate of 5%, so the actual area is 50 * (1 +5%) = 52.5 square.