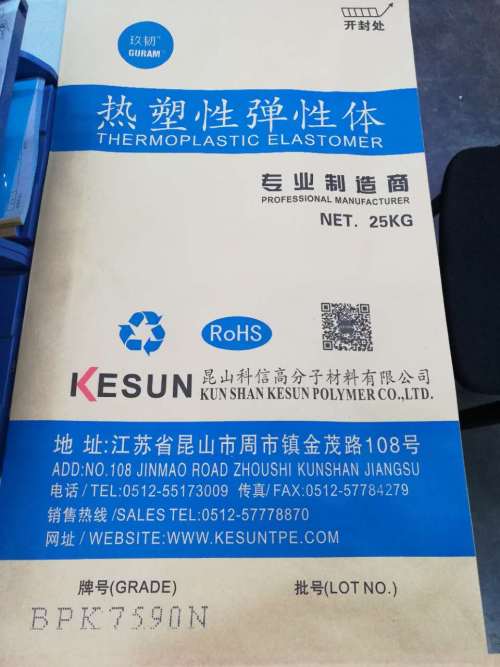

2017 Best selling whosale Thermoplastic Elastomers material chemical resin in China manafacture

- Model

- TPE

Review

Description

Product Features:

The material is safe and recyclable. It is environmental and friendly new materials. It not only has a soft touch, excellent

flexibility, but also has excellent coloring, excellent weather resistance and temperature performance. The material can

be processed by injection molding, extrusion, calendering and blow molding. It has excellent processing stability. It is

widely used in daily goods, sporting goods, toys, building materials, electronic appliances, auto parts and other fields.

BPK7590N is a styrene-based TPE. It has low odor, soft touch, smooth surface and excellent elasticity. BPK7590N is

the injection molding grade specifications for high-end products.

Technical Parameters

|

Molding Processing Guide:

Injection Molding Guide

Shrinkage: 0.015~0.025 inch/inch

Injection Speed: Medium ~High

Injection Pressure: Medium ~High

Back Pressure: Low ~Medium

Holding Pressure: Sufficient Product Film Shape

Cooling: Sufficient Product Cooling Stripping

Extrusion Processing Guide

Aspect Ratio: 20:1-25:1

Compression Ratio: 2.5-3.0

Plate and Filter: Need to Add Plate and Filter

Stretch: 5-10%

Cooling: Sink Cooling

Processing Attention:

A. Generally do not need to dry.if damp,it is recommended drying for 2-4 hours at 60℃.

B. It is advisable to clean the screw and die head with polypropylene or polyethylene before

processing the material.

C. Scraps can be reused.And it need to be dried before use.The amount is generally

not more than 15%. Its performance is basically good.

D. It is coloured with toner and color master batch.Using PE/EVA as the carrier of the master

batch can get a better color matching effect.

Our Company

Picture of Product

Applications

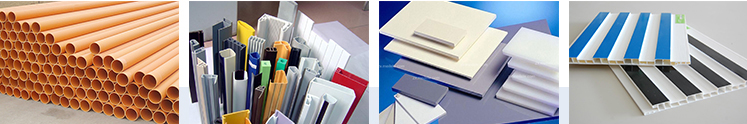

PE wax is recommended for all kinds of PVC applications such as PVC window profile, PVC door, PVC fencing, PVC clear film,

PVC clear sheet, PVC bottle, PVC foam board etc. as lubricant.

Recommended using dosage: 0.3-1.2kg per 100kg PVC resin.

Production Line

Packaging and Shipping

Packing: Composite plastic woven bag, net weight 25kg

Our Team&Services

1. Provide personalized customer's services;

2. Embrace flexibility and professionalism;

3. No lowest price but always value of money;

| 4. | Treat workers and other suppliers as respectful partners.In the past more than10 years, with high quality products and outstanding customer services.Jubang has gained a global sales network, covering Europe, USA, Southeast Asia, India, Africa and South America, etc. |

FAQ

Q: What is your packing?

A: 25kg/bag or as customers' requirement.

Q: What is the payment method?

A: T/T

Q: What is the minimum quantity

A: 17 Tons

Q: What is the means of transport

A: By ocean shipping, from Shanghai port.

Q: How can I get samples?

A: We are honored to offer you PE wax samples free. But you have to pay for the freight.

Q: How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality control from the very begining to the very end.

Our factory has gained SGS authentication. Every batch has its own test report.